You know how the productivity and success of your business can sometimes depend on a single seal or gasket. You know how even a tiny O-ring can make the difference between a good day’s productivity and a bad one. Or if you’re an OEM, how the right part designed and delivered in time can help you get to market faster. You know that uptime is essential, downtime is disastrous, and that maximising one whilst minimising the other is your ultimate goal. In the fast-moving, highly competitive environment we all work in nowadays, you also know how important it is to be flexible, and to optimise availability. All of which means you know how our know-how can help you.For customized solutions to challenging problems, take advantage of our expertise in applications engineering, our profound expertise in material selection in conjunction with sophisticated production technology.

Do you require product support for maintaining your production equipment at peak operational performance? Or are you looking for a source of high quality, value for money, sealing products for your OEM operations? Whichever is the case, we have the solution. If you require a highly efficient supply chain, we can provide it. If you’re looking for maintenance and repairs support, we can provide that too. And when you need to resolve a technical problem, we have the resources to work with you to provide valuable engineering assistance. Whatever your needs, our unique combination of skills can be relied upon to provide cost effective commercial and technical solutions. So for example, if our maintenance team observes a seal to have an abnormally high failure rate, we can draw this to your attention and subsequently re-engineer the application if considered appropriate.

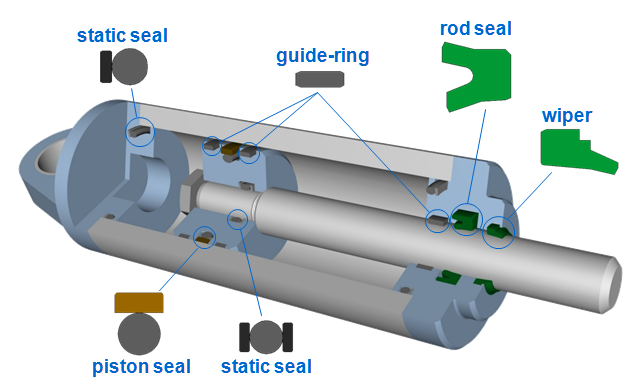

From drawing, CAD visualisations and in-house manufacturing, we can match your requirements for small batch samples or large volume production. And whatever the quantity our products meet the highest quality standards. We are also working on developing next-generation technology, new technical solutions, and specialist compounds to meet the demands of new applications as they emerge. The superior sealing effect can be relied upon to prevent leaks and resultant machine failures, thus saving you costly downtimes. At the same time, both service and repair outlays are reduced. We supplies compact sealing systems that ensure reliable sealing even under the extreme conditions encountered in the wide range of applications. The individual elements involved are optimally matched in terms of both materials and functionality, since all individual seals are developed as a system solution, and supplied from a single source. By selecting materials specifically matched to these requirements, a very high pressure resistance capability is achieved, assuring long, functional life.

Our understanding reaches far beyond sealing technology. Through our consultative partnership approach to customer relationships, we also understand your market and your product and solution requirements, and use this knowledge to inform our product development and the services we offer to ensure we are always proactive.

Our market know-how drives our product development enabling us to create innovative products to meet the changing needs of our customers including OEMs. Our product know-how includes in-depth understanding of product properties and performance from material specifications to styles and types. We also make this knowledge available to you through comprehensive technical documentation, electronic resources, and face-to-face via our engineers. Although product know-how is important, it is the products themselves which are essential. So we make sure we know how best to maintain high product stock levels and availability at all times

Because we know how your industry operates and how your applications work, we are easily able to translate concepts into practical product selections. However, our know-how goes further. We utilise CAD – CAM technology and conduct Finite Element Analysis to minimise design time, and we work with specialist materials for specialist applications with aggressive media, for example. So we not only optimise your existing applications, but also work with you to develop solutions for new applications to improve your efficiency and reduce your costs.

Our know-how is not limited to knowing a great deal about just one aspect of sealing technology. It extends from our customer’s markets to their products and applications and from customisation to logistics and infrastructure. And it makes a difference you can see.

Sometimes it is not what we know, but what we can do with what we know. So if you have a particular concept for your application, you will appreciate our ability to convert that concept into a product specification and ultimately a product. By ‘thinking outside –in-approach’, we can design a product that offers real improvements. Alternatively, we can design to specification and manufacture and supply the necessary sub-assemblies.

Our solutions cover a wide spectrum of pressure and temperature environments, and range from providing sealing against aggressive chemicals, to FDA approved gaskets for the food industry. However, whatever your requirement, if the solution is not already available, we have the know-how to develop, design and manufacture it to meet your precise and individual requirements quickly and cost effectively

Our design and manufacturing know-how encompasses products, materials, processes and applications. So we can create a complete sealing solutions package for you that not only suit your application perfectly, but also help to keep your assets running longer and more efficiently, and reduces maintenance downtime. Our state-of-the-art production system requires no fixed tooling and operates on a CAD - CAM interface, enabling us to provide a fast, flexible manufacturing service with exceptional dimensional replication and consistent quality.

Leaking seals can allow pollutants of all kinds to be released into the environment whether it is simply lubricating oil, or something more toxic from the process itself. For that reason it is essential that every seal you use is right for its application, maintained in optimum condition and replaced as soon as it becomes worn. Our seals are designed for the job of consistent high quality and can be replaced with exact dimensional replicas when worn.

The first step towards reducing emissions and any subsequent pollution is, of course to detect the leak quickly and act on it immediately.

Doing your bit for the environment with the help of our seal is also doing your bit for your bottom line. A high quality seal not only prevents leakage and therefore pollution but also increases operating efficiency. And a high quality seal works more efficiently for longer, reducing downtime, maximising uptime, increasing Mean Time Between Failure, and cutting your Total Cost of Ownership.

Focused to bottleneck and hidden pain areas

Extended seal and asset service life

Best quality with competitive price

Same day dispatch of seals up to 540 mm outer diameter

Counter sale facility

Reliable and Flexible partner for any sealing solutions